Industrial Racks Very Narrow Aisle Pallet Racking in China

Because of narrower forklift channels of the racking system, so they are called Very Narrow Aisle Pallet Rack(VNA Rack). The main body of racking system is a beam-type racking system, and difference is that the action rail of the "three-way stacking forklift" is installed on the ground at the bottom of the rack. The guide rails are conventionally made of unequal angle steel.

Features

1. Large storage, the goods enter and exit is more frequently and have higher picking requirements

2. Urgently needs to increase the number of storage spaces or require a certain amount of storage

3. High level of logistics efficiency requirements

4. The available net height of the warehouse is higher than 6M

5. Can be equipped with a separate storage forklift. It is not recommended to use the storage forklift to drive out and perform other tasks.

Specification

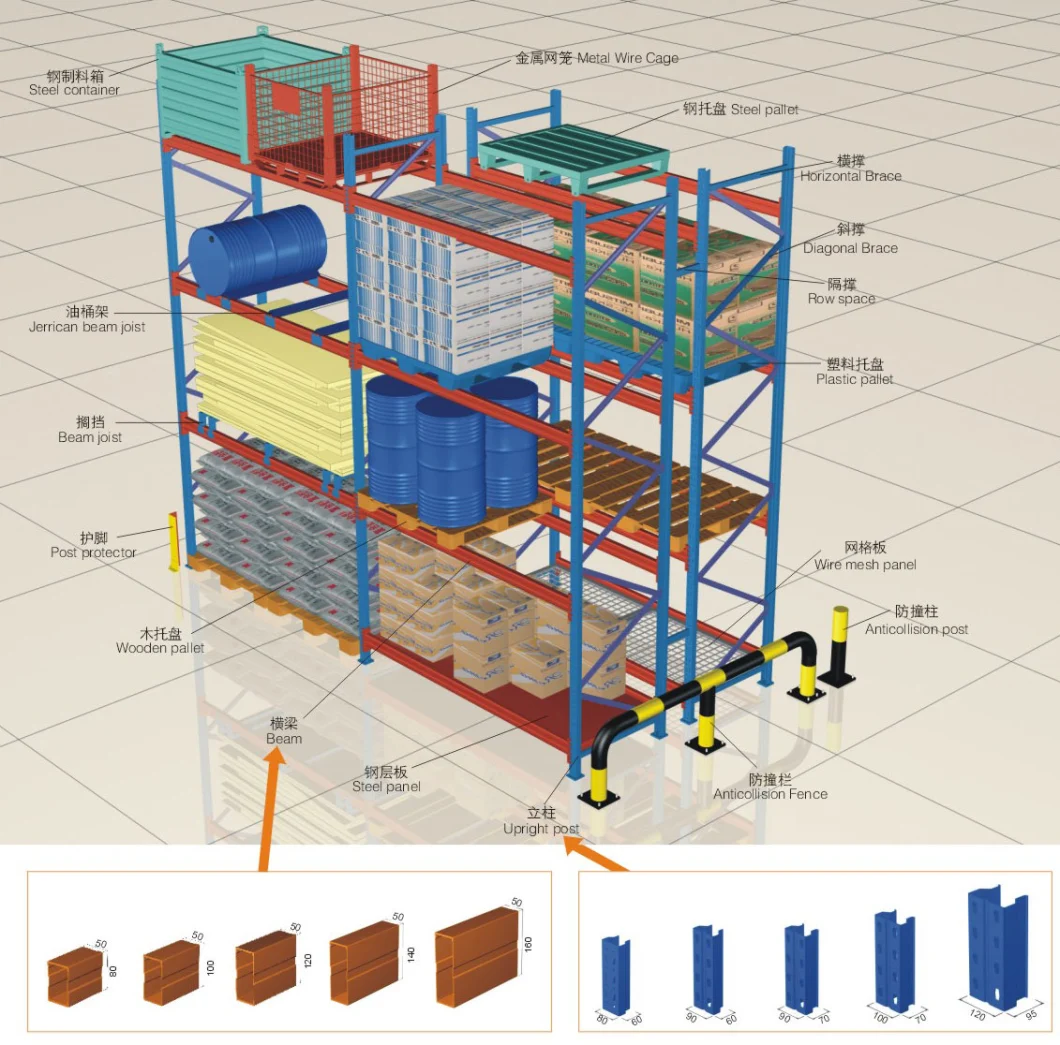

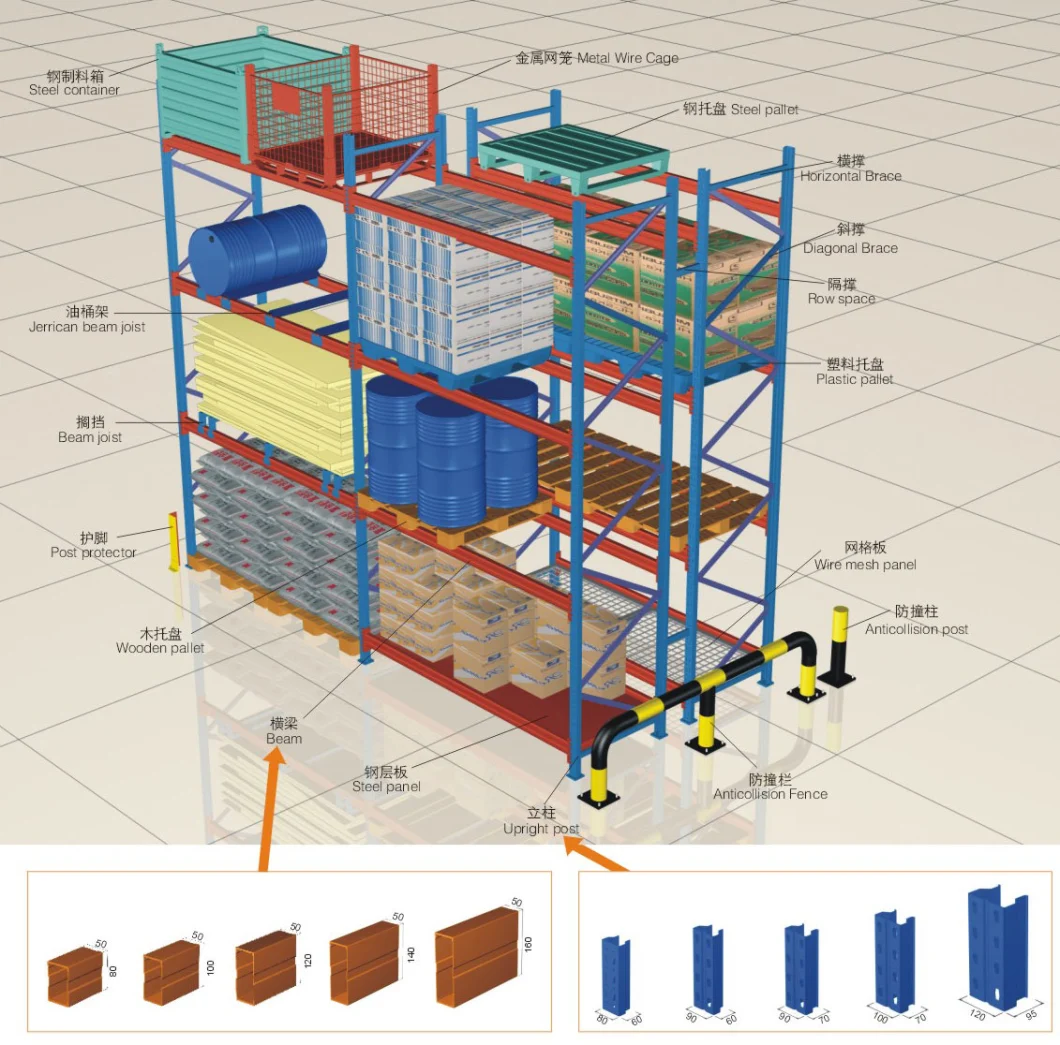

Basic Components

1. Pallet Size (Length*Width*Loading Height in mm)

2. Layout or Dimension (Length*Width*Net Height in mm) of your warehouse

3. Rack Size (Length*Width*Depth in mm) if you are available or we shall design for you

4. How many bays and levels if available

5. Loading Capacity(kg) of each level or each pallet

6. Forklift channel size

7. Is there a fire hydrant, fire hose

8. Whether the installation site is installed on the first floor. If not, the second floor is walking stairs or the elevator (needs to measure the elevator's length)

9. Logistics channel towards

10. Is it a flat warehouse floor

Because of narrower forklift channels of the racking system, so they are called Very Narrow Aisle Pallet Rack(VNA Rack). The main body of racking system is a beam-type racking system, and difference is that the action rail of the "three-way stacking forklift" is installed on the ground at the bottom of the rack. The guide rails are conventionally made of unequal angle steel.

Features

1. Large storage, the goods enter and exit is more frequently and have higher picking requirements

2. Urgently needs to increase the number of storage spaces or require a certain amount of storage

3. High level of logistics efficiency requirements

4. The available net height of the warehouse is higher than 6M

5. Can be equipped with a separate storage forklift. It is not recommended to use the storage forklift to drive out and perform other tasks.

Specification

| Item | Industrial Racks Very Narrow Aisle Pallet Racking System in China |

| Item No.: | SII-BR210 |

| Type: | VAN Steel Racking |

| Rack Bearing Capacity: | About 150-200kgs/level--------Light Warehouse Rack About 200-600kgs/level--------Middle Warehouse Rack About ≥1000kgs/level------Heavy Duty Rack |

| Material: | Q235B Cold-Roll Steel |

| Surface Finish: | Powder Coating |

| Size: | Custom As Requirement |

| Component: | Upright, Beam, Bracing |

| Supply Ability: | 300-400 ton per month |

| Sample Time: | About 7-10 working days |

Basic Components

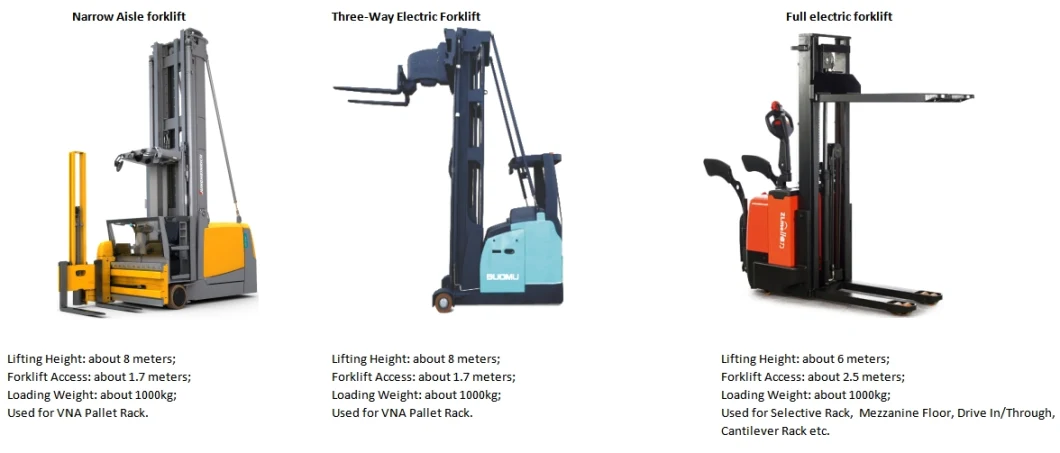

Forklift for Different Racking

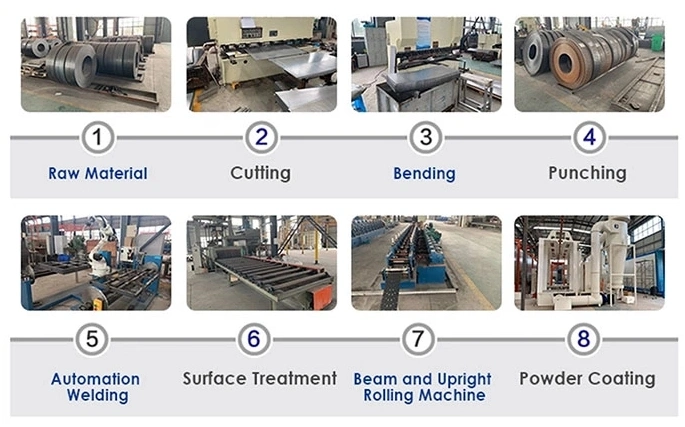

Custom Whole Process

Packing Details

1. Pallet Size (Length*Width*Loading Height in mm)

2. Layout or Dimension (Length*Width*Net Height in mm) of your warehouse

3. Rack Size (Length*Width*Depth in mm) if you are available or we shall design for you

4. How many bays and levels if available

5. Loading Capacity(kg) of each level or each pallet

6. Forklift channel size

7. Is there a fire hydrant, fire hose

8. Whether the installation site is installed on the first floor. If not, the second floor is walking stairs or the elevator (needs to measure the elevator's length)

9. Logistics channel towards

10. Is it a flat warehouse floor